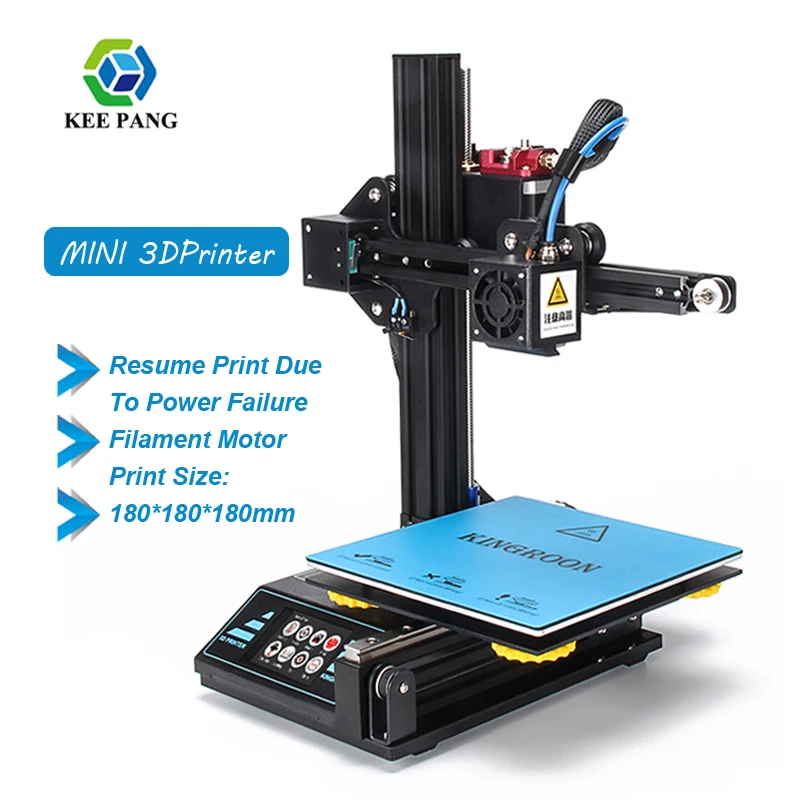

Get Best 3D Printer KP3 DIY Impresora 3D Upgraded High Precision Magnetic Plate Resume Printing KIT Size 180

The Latest 3D Printer KP3 DIY Impresora 3D Upgraded High Precision Magnetic Plate Resume Printing KIT Size 180

Check out our sale items 3D Printer KP3 DIY Impresora 3D Upgraded High Precision Magnetic Plate Resume Printing KIT Size 180 and enjoy forgive customary Shipping on

Shop our 3D Printer KP3 DIY Impresora 3D Upgraded High Precision Magnetic Plate Resume Printing KIT Size 180 with price US $298.00 , And get 49%OFF

3D Printer parts Heat Insulation Cotton 200/220/235/310mm Foil Self-adhesive Insulation Cotton 3D Printer Heating Bed Sticker

[33034362122

How to get coupons and don't forget put in the coupon code when you pay

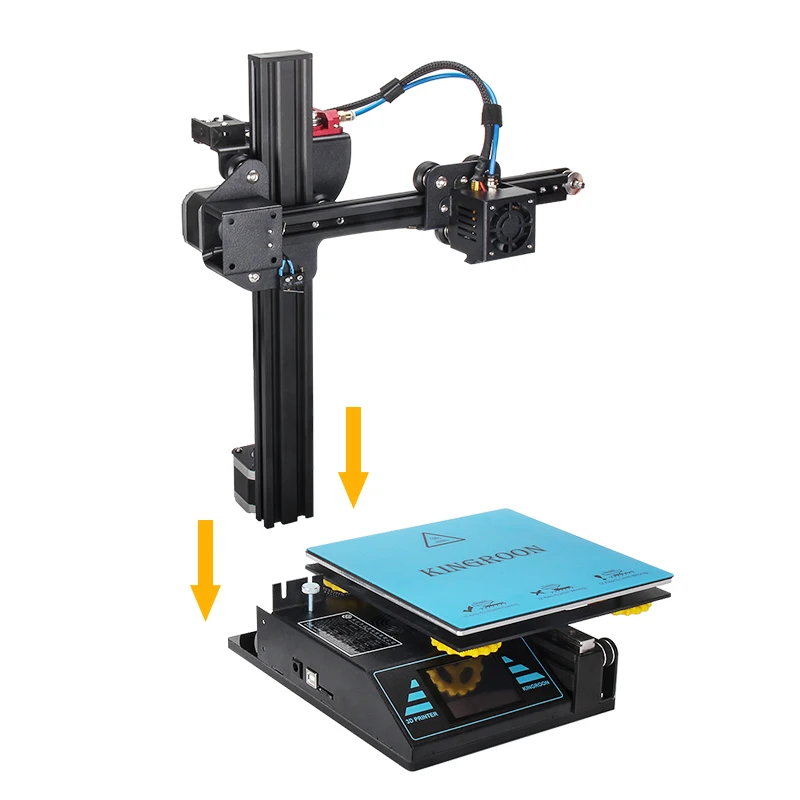

Product ParametersModel Number : KP3 Build Size: 180*180*180mm Printing Technology: FDMNozzle quantity: 1Print precision: 0.1-0.4mmNozzle: 0.4mmFilament Diameter: 1.75mmFilament: PLA/Wood/TPU/ABSNozzle Temperature: ≤260℃Hot bed Temperature: ≤110℃File type: STL/Obj/AfmPrinting via: USB cable and TF cardSoftware: Cura/Slicer/Repetier-HostOperating systems: Windows XP/Vista/7/8/10/Mac/linuxScreen language: CN/EN/RU/ES/FR/ITMax Travel Speed: 200mm/sMax Print Speed: 100mm/sPrint Speed: ≤60mm/sResume print due to power failure: YesFilament Motor: YesAoto Living: N/AMachine Power: 240WRated voltage: 220V-50hz 110V-60hzPower Supply: 24V/15A/360WMachine Size: 275x310x370mmWeight: 7kg

Frequently asked questions1The nozzle is blocked, the filament can not be extruded, how to deal with?Checking to see the distance between the nozzle and the hotbed is that suitable or not,clear the nozzle(Note: The new nozzle can not use the wrench going inside to clear the nozzle, pls heat the nozzle to 230 degree, the residue will flow out automatically).Meantime pls check the gear and motor shaft working or not. If the motor gear around by the powder, pls clear the powder.Checking to see whether the distance of nozzle is too small, if so, pls recalibrate the hotbedAt the same time, you can also increase the printing temperature by 5-10 degrees.Note: pls recalibrate the hot bed after clear the nozzle, because used the wrench to clear the nozzle will lead to the nozzle downward shift and make the distance more small. When the distance is too small, the nozzle will be block up again.2Printing models can not be molded, the extruded filament is like a ramenThe situation indicates that the distance between the nozzle and the hotbed is too large. Please recalibrate the distance.3The nozzle does not extrude the filament, but the filament can be pressed down by hand.The nozzle is heated to 230 degrees to clean the nozzle. When the nozzle temperature reaches 230 degree, the residue will flow out automatically.Then checking whether the gear of the motor is worn due to the long-term use of the gear. Maybe considered to replace the motor gear.4The sound of a squeaking noise after the nozzle is fed into the filamentThe filament is not at suitable position inserted, pls withdrawn the filament, and check whether the broken filament inside the motor gear, pls clear the broken filament and fed into the filament again. 5X-axis misalignment occurs in half of printingOffline print model misplacementThere is a problem with the motor cable or beltThe motor line or switch line signal interfered, it is recommended to print a few different models to check again.Checking to see whether the motor cable plug and belt are loose, after checking, printing the model to see whether it still doesn't work. If still not working, pls replace the new line.Online printing: It may be affected by communication anomalies, such as sudden interruption of communication, etc.

Related Product :

Kee Pang 3D Printer PLA Filament 1.75mm Filament Dimensional Accuracy+/-0.02mm 1KG 300M 2.2LBS 3D Printing Material for RepRap : Click Here Kee Pang DC Cooling Fan 4020 5015 Turbo fan 2510 3010 4010 5010 6010 Fan 12V/24V Hot End Extruder For MakerBot RepRap Printer : Click Here T8 Lead Screw OD 8mm Pitch 2mm Lead 2mm 100mm 150mm 200mm 250mm 300mm 330mm 350mm 400mm 500mm with Brass Nut for Reprap 3D Print : Click Here

Comments

Post a Comment